A water curtain sprinkler creates a solid barrier of water to stop fire from spreading. Specialized nozzles release water in a controlled pattern. This barrier shields people, property, and escape paths during emergencies.

Fire safety experts recommend water curtain sprinklers for areas that need extra protection from heat and smoke.

Key Takeaways

- Water curtain sprinklers create a strong water barrier that blocks fire, heat, and smoke, protecting people and property during emergencies.

- These systems use special open nozzles and flexible spray patterns to form continuous water walls, making them ideal for protecting openings, escape routes, and unique building features.

- Regular inspection, proper design, and compliance with fire safety codes ensure water curtain sprinklers work effectively and provide reliable fire protection.

Water Curtain Sprinkler: Definition

A water curtain sprinkler serves as a specialized fire protection device designed to create a continuous barrier of water. According to fire safety standards such as NFPA 13 and local building codes, this system consists of a line of closely spaced sprinklers or a single sprinkler, often installed with draft stops. These sprinklers activate automatically and form a water wall that retards the passage of fire, heat, and smoke through openings. Building codes, like those in Los Angeles, recognize water curtain sprinklers as an alternative to fire doors or shutters, especially for protecting glazed openings or escape routes. The system must use approved automatic sprinklers, positioned on the occupied side of the opening, and spaced to provide protection equivalent to a fire-rated barrier.

What Makes It Unique

Several features set the water curtain sprinkler apart from standard fire sprinklers:

- It uses open sprinkler heads or drench nozzles designed to produce a uniform sheet of water.

- The system offers multiple spray angles, such as 45°, 60°, 90°, 120°, and 150°, to suit different architectural needs.

- Water curtain sprinklers operate at a working pressure of about 0.35 MPa and are typically constructed from brass or stainless steel for durability.

- The primary function is to create a physical water barrier, not just to suppress flames.

| Feature | Water Curtain Sprinkler Characteristics |

|---|---|

| Sprinkler Head Type | Open sprinkler with a single outlet |

| Spray Angles | 45°, 60°, 90°, 120°, 150° |

| Fire Sprinkler Type | Drench nozzle, water curtain effect |

| Application | Firefighting, fire water systems, deluge valve systems |

| Material | Brass or stainless steel |

| Working Pressure | Approximately 0.35 MPa |

Comparison to Standard Sprinklers

Standard fire sprinklers focus on extinguishing or controlling fires by spraying water directly onto the flames. They usually feature closed heads that activate individually when exposed to heat. In contrast, a water curtain sprinkler system uses open heads or nozzles that release water simultaneously to form a continuous barrier. This design blocks the spread of fire, heat, and smoke through vulnerable openings, such as doorways, windows, or conveyor penetrations. While standard sprinklers protect specific areas, water curtain sprinklers provide a protective shield, making them ideal for separating fire zones or safeguarding escape routes.

Purpose of Water Curtain Sprinklers

Fire Containment and Separation

Water curtain sprinklers play a critical role in fire safety by creating a physical barrier that limits the spread of flames and hot gases. Building designers often install these systems around vertical openings, such as glass walls and atriums, to block fire from moving between spaces. The curtain of water cools the area and prevents superheated gases from passing through, which helps protect adjacent corridors and rooms. Many building codes, including the International Building Code (IBC), allow water curtain sprinklers as an alternative to fire-rated glazing. This approach maintains fire separation without the need for expensive fire-rated glass. Sprinklers are usually closely spaced on both sides of glass walls or openings, ensuring the glass remains protected and the fire barrier stays intact.

Water curtain sprinklers often operate on a separate branch line, which increases system reliability and ensures fire separation even if other sprinklers fail.

Protection of Openings and Escape Routes

Protecting escape routes during a fire is essential for occupant safety. Water curtain sprinklers form a dense wall of water droplets that blocks radiant heat, flames, and smoke from entering doorways and passageways. High-rise buildings use these systems to prevent fire from spreading between floors and to safeguard both people and property. Studies and simulations in environments like road tunnels show that water curtains reduce temperature, smoke, and toxic gases, making evacuation safer. These improvements increase the time available for occupants to escape, especially when other fire-blocking methods are not practical.

- Water curtain sprinklers provide a reliable solution for maintaining safe egress routes during emergencies.

How Water Curtain Sprinklers Work

The Water Curtain Effect

The water curtain effect relies on the ability of water droplets to absorb and scatter thermal radiation. When a water curtain sprinkler activates, it releases a dense sheet of water droplets into the air. These droplets form a physical barrier that blocks heat and flames from passing through. Scientists explain this process using Mie theory, which describes how water droplets interact with thermal radiation. The droplets reduce the amount of heat that can travel through the barrier by absorbing and scattering the energy. As the pressure and width of the water curtain increase, the barrier becomes more effective at blocking heat. Experimental studies confirm that large water droplets provide stability, even in outdoor environments with wind. This stability ensures that the water curtain remains intact and continues to shield against fire and heat.

Water curtains not only block heat but also lower the temperature of flames, making them a powerful tool for fire prevention and control.

Fire Suppression and Heat Blocking

Water curtain sprinklers suppress fire and block heat through several mechanisms. The system cools burning surfaces, reduces the temperature of combustion products, and displaces oxygen near the fire. These actions slow down the spread of flames and make it harder for the fire to grow. The effectiveness of the water curtain depends on factors such as droplet size, spray intensity, and curtain thickness. Droplets with a diameter of 2–4 micrometers provide the best thermal radiation shielding. The table below highlights how water curtain sprinklers compare to other fire protection systems:

| Aspect | Summary | Impact on Fire Protection |

|---|---|---|

| Droplet Size | 2–4 μm optimal for heat blocking | Shields radiant heat, controls oxygen |

| Curtain Thickness | 100–400 mm effective | Absorbs heat, improves efficiency |

| Smoke Blocking | Depends on spray intensity | Enhances visibility, aids evacuation |

| Access | Allows movement through curtain | Firefighters can enter protected areas |

| Suppression Mechanism | Cools, blocks heat, displaces oxygen | Directly suppresses fire spread |

Water curtain sprinklers offer unique advantages. They allow people and equipment to pass through while still providing a strong barrier against heat and smoke. This flexibility makes them valuable in many fire protection scenarios.

Main Components of a Water Curtain Sprinkler System

Nozzles and Spray Patterns

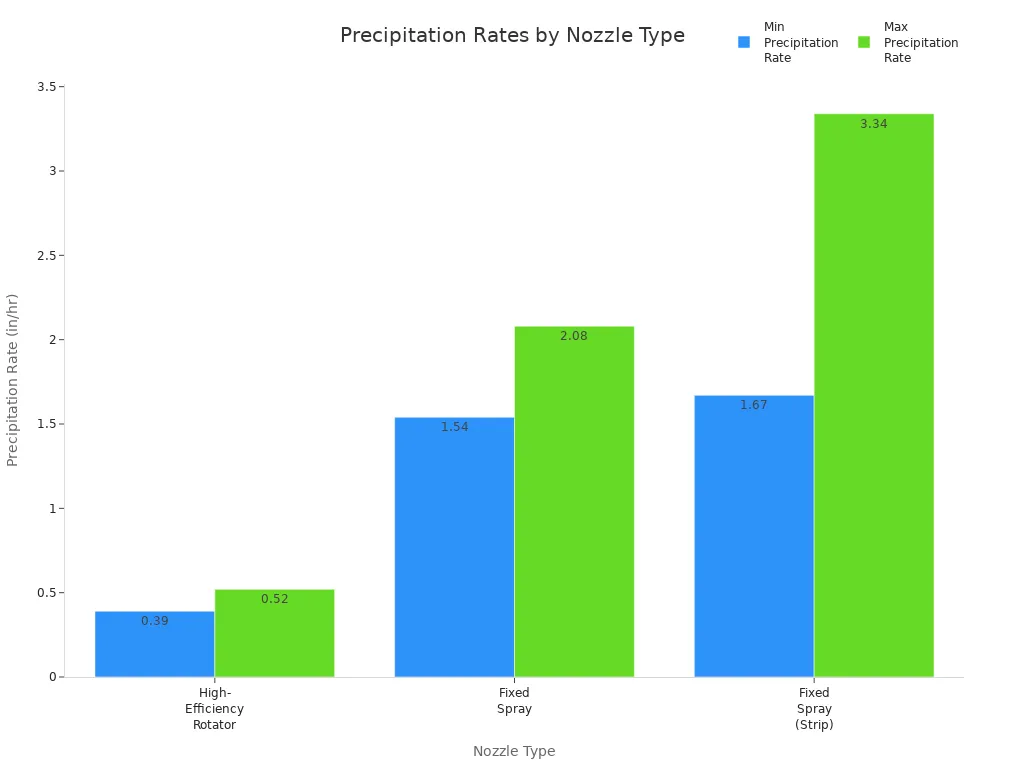

Nozzles serve as the heart of any water curtain sprinkler system. They determine how water is distributed and how effectively the system forms a protective barrier. Different nozzle types offer unique spray patterns:

- Fixed spray nozzles create a fan-shaped spray. Their arc and radius can be adjusted, which allows precise control over the flow rate and coverage area.

- Rotary nozzles emit rotating streams of water. These nozzles can also be adjusted for radius and arc, providing efficient debris clearing and matched precipitation.

- Spray patterns directly influence water efficiency, uniformity, and the area covered. This control helps the system suppress fires quickly by distributing water where it is needed most.

| Nozzle Type | Radius Range (ft) | Arc Range (degrees) | Precipitation Rate (in/hr) |

|---|---|---|---|

| High-Efficiency Rotator | 8 – 35 | 45°-105°, 90°-210°, 210°-270°, 360° | 0.39 – 0.52 |

| Fixed Spray | 5 – 17 | 90°, 120°, 180°, 360° | 1.54 – 2.08 |

| Fixed Spray (Strip Nozzles) | 5 and 9 wide strips | 90°, 180° | 1.67 – 3.34 |

A water curtain sprinkler with flexible spray patterns can adapt to different fire scenarios, improving fire suppression and minimizing damage.

Water Supply and Piping

Proper water supply and piping design ensure the system delivers enough water to form an effective barrier. According to NFPA 13 standards, the system must provide at least 3 gallons per minute per linear foot of water curtain, with each sprinkler discharging no less than 15 gallons per minute. Engineers calculate the number of sprinklers based on the length of the protected opening. The hydraulic design must also account for ceiling sprinklers near the water curtain.

Dry-pipe arrangements are possible, but they require input from a professional engineer to set the correct flow, pressure, and sprinkler k-factor. Installation rules specify maximum and minimum distances from ceilings and walls, as well as spacing between sprinklers. For example, sprinklers should be installed within 12 inches of the ceiling and spaced 6 to 15 feet apart, depending on the rating. Local building codes may require even closer spacing for exterior wall openings. Professional assessment ensures compliance and system reliability.

Activation Process of Water Curtain Sprinklers

Automatic and Manual Activation

Water curtain systems can activate in two main ways. Automatic activation relies on sensors or detectors that sense fire conditions. When these devices detect heat or smoke, they send a signal to open the system’s control valve. Water then flows through the nozzles, forming a protective barrier. This process happens quickly and does not require human intervention. In contrast, manual activation depends on trained personnel. They may use a control panel or a dedicated switch to start the system. Manual activation often serves as a backup in case automatic systems fail or when staff need to respond to a specific threat. Both methods ensure that the water curtain forms at the right time to contain fire and protect escape routes.

Tip: Regular training and clear signage help staff respond quickly during emergencies.

Detection and Control Methods

Modern water curtain systems use advanced detection and control technologies to improve reliability. Smoke detectors and heat detectors play a key role. These devices sense fire conditions and send electrical signals to the system’s control unit. The control unit then operates a preaction or deluge valve, often using a solenoid mechanism. Preaction systems keep the piping filled with air at low pressure until a detector triggers the valve. Water only enters the pipes and discharges through the nozzles when both the detector and the sprinkler head activate. This dual-action approach prevents accidental water release, making it ideal for sensitive areas like museums or libraries.

| Aspect | Description |

|---|---|

| Detection Technologies | Smoke detectors and heat detectors that sense fire conditions and send electrical signals. |

| Control Technologies | Preaction valves (also called deluge valves) operated via solenoid valves triggered by detectors. |

| Activation Mechanism | Requires two simultaneous conditions: sprinkler head opens due to heat AND detector signal triggers valve. |

| System Usage | Commonly used in sensitive or high-value areas (e.g., museums, libraries) to prevent accidental discharge. |

| Water Curtain Formation | Water flows through sprinkler nozzles creating a barrier to contain fire and protect areas. |

These detection and control methods ensure the system responds only when necessary, reducing the risk of water damage while maintaining strong fire protection.

Typical Applications for Water Curtain Sprinklers

Industrial and Commercial Settings

Many industries rely on water curtain systems to protect critical infrastructure and personnel. Facilities that handle combustible materials or operate in high-risk environments often require enhanced fire protection. Common locations include:

- Wood processing centers, where sawdust and timber increase fire risk.

- Oil refineries, which handle flammable liquids and gases.

- Power plants, where electrical equipment and fuel sources create potential hazards.

- Other high hazard industrial facilities, such as chemical plants and manufacturing sites.

Commercial buildings also benefit from these systems. High-rise buildings use water curtains to prevent fire from spreading between floors and to shield occupants from radiant heat. Tunnels and bridges incorporate these systems to protect structural elements and maintain safe evacuation routes during emergencies. Oil and gas facilities, with their unique fire risks, frequently install water curtains as part of their comprehensive safety strategies.

Note: Water curtain systems provide a reliable solution for environments where traditional fire barriers may not be practical or effective.

Special Use Cases (Openings, Conveyors, Glass Walls)

Engineers often specify water curtain systems for unique architectural or operational challenges. Openings in fire-rated walls, such as doorways or large windows, require additional protection to maintain compartmentation. Water curtains form a barrier across these gaps, ensuring fire and smoke do not pass through.

Conveyor systems that penetrate fire-rated separations present another challenge. Water curtains installed at these points prevent fire from traveling along the conveyor path. Glass walls and atriums, popular in modern architecture, lack inherent fire resistance. Water curtains installed along these features protect both the structure and occupants without compromising aesthetics or visibility.

Tip: Proper placement and design of water curtain systems maximize their effectiveness in these specialized scenarios.

Benefits of Water Curtain Sprinklers

Enhanced Fire Protection

Fire safety experts recognize several key advantages of water curtain systems. These systems create a robust barrier that stops fire, flames, heat, and smoke from moving between protected areas. The water wall acts as a radiant heat shield, which protects structures, equipment, and people from intense heat. The cooling effect lowers the temperature of surfaces and the surrounding air, making fire control more effective. Firefighters benefit from reduced heat intensity and flame impact, which allows them to approach hazardous zones more safely. The system also helps control smoke and hazardous gases, improving visibility and air quality for safer evacuation and firefighting.

- Prevents the spread of fire, flames, heat, and smoke between areas.

- Shields structures, equipment, and personnel from radiant heat damage.

- Lowers temperatures of surfaces and air, aiding fire control.

- Reduces heat intensity and flame impact for firefighter safety.

- Controls smoke and hazardous gases, improving visibility and air quality.

Note: Enhanced fire protection increases the chances of containing a fire before it spreads to critical areas.

Flexibility and Versatility

Water curtain sprinkler systems adapt to a wide range of building layouts and fire protection needs. Engineers can install these systems in industrial plants, commercial buildings, tunnels, and even areas with unique architectural features. The ability to customize spray patterns and coverage areas allows for targeted protection of openings, glass walls, and conveyor penetrations. This versatility ensures that the system meets the specific requirements of each project. Facility managers appreciate the system’s ability to provide both permanent and temporary fire barriers, depending on operational demands.

Limitations of Water Curtain Sprinklers

Water Usage and Drainage Needs

Water curtain systems require a significant amount of water to create an effective barrier. Facilities must ensure a reliable and high-capacity water supply. In many cases, the system discharges hundreds of gallons per minute during activation. This high flow rate can overwhelm standard drainage systems if not properly designed. Engineers must plan for rapid water removal to prevent flooding or water damage in protected areas.

Note: In older buildings, retrofitting adequate drainage may present challenges. Facility managers should assess existing infrastructure before installation.

Key considerations for water usage and drainage include:

- Sizing of water storage tanks and pumps

- Capacity of floor drains and sump pumps

- Risk of water accumulation in sensitive areas

A well-designed drainage system protects both property and occupants from secondary water hazards.

Suitability for Different Fire Types

Water curtain systems perform best against fires involving ordinary combustibles, such as wood, paper, or textiles. However, they may not suit all fire scenarios. Fires involving flammable liquids, electrical equipment, or reactive chemicals often require specialized suppression agents. Water can spread certain fires or create electrical hazards.

The table below summarizes suitability:

| Fire Type | Water Curtain System Effectiveness |

|---|---|

| Ordinary combustibles | High |

| Flammable liquids | Low |

| Electrical fires | Low |

| Reactive chemicals | Low |

Facility managers should evaluate fire risks and select the most appropriate protection method for each area.

Maintenance Requirements for Water Curtain Sprinklers

Regular Inspection and Testing

Routine inspection and testing keep fire protection systems reliable. Facility managers should follow a structured schedule to ensure all components work as intended. According to NFPA 25 standards, inspections and tests must occur at least semi-annually and annually.

- Semi-annual inspections include checking water flow alarm devices, supervisory switches, system gauges, hydraulic data plates, pressure-reducing valves, and fire department siamese connections.

- Annual inspections cover all semi-annual tasks. They also require additional flow tests, visual checks of system components, full operation of control valves, lubrication of operating stems, and more comprehensive evaluations.

Regular inspections help identify issues early, reducing the risk of system failure during an emergency.

System Upkeep

Proper upkeep extends the lifespan of the sprinkler system and ensures optimal performance. Maintenance teams should clean nozzles to prevent blockages and check for corrosion or leaks in pipes and fittings. They must verify that control valves remain accessible and clearly labeled. Technicians should also test alarm and detection devices to confirm they activate as designed.

A maintenance log provides a record of all inspections, repairs, and replacements. This documentation supports compliance with fire codes and helps track recurring issues. Facility managers should train staff to recognize signs of wear or malfunction and report them promptly.

Consistent upkeep and thorough documentation build confidence in the system’s ability to protect people and property.

Key Considerations for Installation and Use

Compliance with Codes and Standards

Installers must follow strict codes and standards to ensure fire protection systems perform as intended. NFPA 13 (2022 edition) serves as the primary standard for water curtain systems. This code requires each system to deliver at least 3 gallons per minute per linear foot of curtain, with no individual sprinkler discharging less than 15 gallons per minute. The number of sprinklers must match the length of the protected opening, as specified in the code. Hydraulic calculations must include the water supply for the curtain, ensuring the system can operate effectively during a fire event. Chapter 19, Section 19.3.3 of NFPA 13 outlines these requirements in detail. Building owners and contractors should always verify that their designs and installations meet these standards to avoid compliance issues and ensure occupant safety.

Tip: Always consult the latest edition of NFPA 13 and local building codes before starting any installation project.

Professional Assessment and Design

Professional assessment and design play a crucial role in the effectiveness of water curtain systems. Many applications involve unique architectural features or nonstandard fire risks. NFPA standards may not specify every design detail, especially for systems that protect glass walls, structural members, or specialized equipment. Engineers must define clear performance objectives and discharge criteria for each project. They use hydraulic calculations to determine storage tank capacity, pump size, and pipe layout. In some cases, engineers apply computational fluid dynamics (CFD) to model spray patterns and droplet distribution. Full-scale fire tests may be necessary to confirm system performance in new or complex scenarios. This level of detail ensures the system meets safety goals and provides reliable protection.

Note: A qualified fire protection engineer can tailor the system to the building’s unique needs, reducing the risk of inadequate coverage or noncompliance.

Understanding water curtain sprinkler systems helps building owners make informed decisions about fire safety. Key points include:

- Codes like IBC and NFPA 13 reference these systems for protecting openings.

- Proper use demands compliance with regulations, clear specifications, and involvement from fire protection engineers.

- Design flexibility exists, but misuse remains common.

FAQ

How often should a water curtain sprinkler system undergo inspection?

Facility managers should schedule inspections at least twice a year. Regular checks help ensure the system operates correctly during emergencies.

Can water curtain sprinklers replace fire-rated doors or shutters?

Building codes sometimes allow water curtain sprinklers as alternatives. Engineers must verify compliance with local regulations before making substitutions.

What is the typical water pressure required for water curtain sprinklers?

Most systems operate at approximately 0.35 MPa. This pressure ensures the water forms an effective barrier against fire and heat.

Post time: Jul-16-2025