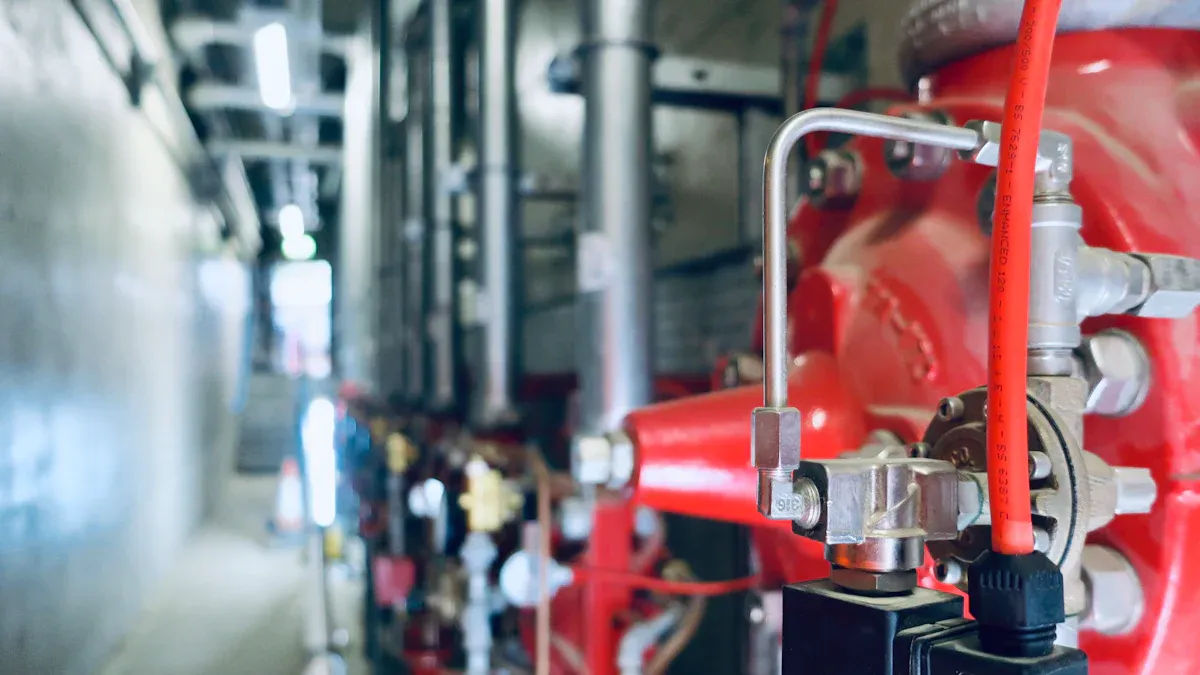

Brass deluge fire sprinkler head technology delivers unmatched durability and reliability. Fire safety professionals recognize its unique brass composition for resisting corrosion and withstanding extreme temperatures. This trusted component has earned a reputation for advancing fire protection and remains a benchmark of innovation within the industry.

Key Takeaways

- Brass deluge fire sprinkler heads provide fast, area-wide fire suppression by releasing water simultaneously across high-risk zones, making them ideal for industrial and hazardous environments.

- The brass material offers excellent durability and corrosion resistance, ensuring long-lasting performance even in harsh conditions with minimal maintenance.

- These sprinkler heads combine innovative design and reliable operation to protect large spaces efficiently, saving resources and meeting modern fire safety standards.

Evolution of Fire Sprinkler Systems

Early Innovations in Fire Suppression

Ancient civilizations laid the foundation for modern fire suppression. Mesopotamians built clay conduits to deliver water, while Egyptians invented the siphona, a hand-operated pump that projected water onto flames. Greek inventor Ctesibius improved fire pumps with double-action pistons, and the Romans established the Vigiles Urbani, the first organized firefighting force. These early systems relied on manual labor and basic water delivery, which limited their effectiveness. Over time, cities introduced bell towers for fire alerts, but true progress came with the development of automatic fire alarms and sprinkler systems, which enabled faster detection and targeted suppression.

Key Milestones in Sprinkler Technology

Significant advancements in fire sprinkler systems have shaped modern fire safety. The table below highlights key milestones:

| Year | Contributor/Innovation | Description |

|---|---|---|

| 1812 | William Congreve | First building-wide sprinkler system using perforated pipes |

| 1864 | Major A Stewart Harrison | First modern sprinkler head with heat-activated release |

| 1872 | Philip W. Pratt | Patented first automatic sprinkler system |

| 1874 | Henry S. Parmelee | Developed practical automated sprinkler head |

| 1890 | Frederick Grinnell | Invented glass disc sprinkler, a standard still used today |

| 1953 | Factory Mutual Research | Introduced spray pattern sprinkler |

| 2011+ | Governments | Mandated sprinkler installation and advanced monitoring |

These milestones reflect the transition from manual to automated systems, improving both speed and reliability in fire suppression.

Emergence of Specialized Sprinkler Heads

Specialized sprinkler heads, such as the brass deluge fire sprinkler head, transformed fire suppression strategies. Unlike traditional heads that activate individually, deluge systems use open heads and release water simultaneously across a hazard area when triggered by a fire alarm. This rapid, widespread response is critical in environments where fire can spread quickly. The introduction of these specialized heads allowed fire protection professionals to tailor suppression systems to specific risks, increasing both flexibility and effectiveness.

Brass Deluge Fire Sprinkler Head: Design and Advantages

Introduction and Function in Deluge Systems

Brass deluge fire sprinkler heads play a vital role in high-hazard fire protection systems. These sprinkler heads remain open and connect directly to a dedicated water supply. When a fire detection system senses heat or smoke, it triggers the deluge valve. This action releases water through every sprinkler head at once, flooding the entire protected area. The immediate and simultaneous discharge of water ensures rapid suppression, which is essential in environments where fire can spread quickly. Deluge systems often protect industrial sites such as chemical plants, oil refineries, tunnels, offshore platforms, and power plants. These locations contain flammable or explosive materials, making fast and comprehensive fire suppression critical.

Key features of brass deluge fire sprinkler heads in these systems include:

- Open head design for simultaneous water discharge.

- Connection to a dedicated water supply for immediate response.

- Rapid area-wide flooding upon activation.

- Use in high-risk environments requiring robust fire protection.

Material Benefits of Brass

Brass offers several advantages as a material for deluge fire sprinkler heads. Its exceptional durability and corrosion resistance make it ideal for demanding fire protection applications. Brass construction ensures that the deluge valve and sprinkler head can withstand exposure to moisture and harsh environments, maintaining functionality over time. The material’s industrial quality meets strict safety regulations and supports long service life with minimal maintenance.

Note: Advanced surface treatments, such as electroless nickel plating or Nedox plating, can further enhance brass’s corrosion resistance, making it comparable to stainless steel in salt-laden or offshore atmospheres.

Brass also provides efficient water flow management, which is crucial for rapid response during emergencies. Dezincification resistant (DZR) brass is often used for water spray nozzles to prevent zinc loss from water exposure, especially in challenging environments. These properties collectively contribute to the reliability and longevity of brass deluge fire sprinkler heads.

Operational Performance and Reliability

The operational performance of brass deluge fire sprinkler heads sets them apart from other types. Their design incorporates several features that ensure effective fire suppression:

- Hydraulic rotation enables a 360-degree water spray, distributing water evenly over large areas.

- Built-in temperature sensing glass bulbs meet standard activation requirements.

- Reliable water pressure sealing allows operation under low working pressure.

- Compact size and light weight simplify installation and reduce engineering workload.

- Industrial-grade surface treatments provide strong corrosion resistance.

Performance metrics such as the Response Time Index (RTI) help evaluate the effectiveness of these sprinkler heads. RTI measures the thermal sensitivity and activation speed of the heat-responsive element. Lower RTI values indicate faster response times, which are essential for life safety and quick fire suppression.

| Sprinkler Type | RTI Range (m·s)¹/² | Purpose |

|---|---|---|

| Fast Response | ≤ 50 | Life safety, quick suppression |

| Special Response | 50–80 | Balance between speed and control |

| Standard Response | ≥ 80 | Property protection, containment |

Brass deluge fire sprinkler heads also help save 20-35% of system pipe consumption, reducing the load on the pipe network and overall engineering requirements. Their robust design and reliable operation make them a preferred choice for protecting large, high-risk spaces such as multi-storey factories, warehouses, shopping malls, and open storage yards.

Comparing Brass Deluge Fire Sprinkler Head to Other Types

Differences from Standard Sprinkler Heads

Brass deluge fire sprinkler heads differ significantly from standard sprinkler heads in both design and function. Standard sprinkler heads activate individually when heat from a fire reaches a specific temperature, releasing water only in the affected area. In contrast, deluge heads remain open and discharge water simultaneously across the entire protected zone when the system detects fire. This approach provides rapid, area-wide suppression, which is essential in high-hazard environments.

Material selection also sets these heads apart. Brass and bronze heads require corrosion-resistant coatings, such as polyester paint or electroless nickel, to protect exposed metal. Stainless steel heads offer inherent corrosion resistance, making them suitable for corrosive environments without additional coatings. Plastic is not commonly used for fire sprinkler heads due to lower durability and temperature resistance.

| Feature | Brass Heads (Deluge) | Stainless Steel Heads | Plastic Heads |

|---|---|---|---|

| Corrosion Resistance | Requires coating | Inherent | Not standard |

| Durability | High | High | Low |

| Temperature Tolerance | Excellent | Excellent | Moderate |

| Application | Industrial, high-risk | Corrosive, industrial | Not recommended |

Unique Contributions to Fire Safety

Brass deluge fire sprinkler heads contribute unique advantages to fire safety. Their open-head design ensures immediate and comprehensive water coverage, which is vital for controlling fires in environments with flammable liquids or rapid fire spread. The mechanical strength and corrosion resistance of brass, especially alloys like C84400, support long-term reliability. Manufacturers use advanced casting techniques to produce components that withstand high-pressure water flow and mechanical stress. These features help maintain system integrity and operational readiness over decades.

Recent advancements have further improved performance. Rapid response technology enables faster activation, while foam-water deluge heads combine water and foam for enhanced suppression of flammable liquid fires. These innovations demonstrate the adaptability and ongoing improvement of brass deluge fire sprinkler head technology.

Continued Relevance in Modern Fire Protection

Brass deluge fire sprinkler heads remain relevant in modern fire protection due to their proven durability and reliability. High-hazard facilities, such as chemical plants and refineries, continue to rely on these heads for comprehensive fire suppression. Brass withstands constant exposure to water and harsh conditions without rusting or scaling, ensuring long service life. The industry’s focus on corrosion resistance and mechanical strength keeps brass at the forefront of fire safety solutions. As technology advances, manufacturers refine brass head designs to meet evolving safety standards and specialized application needs.

Brass deluge fire sprinkler head technology has shaped modern fire protection. Its durable material and innovative design set new standards for reliability. Fire safety professionals continue to trust this solution. The industry recognizes its lasting impact and values ongoing innovation in fire suppression systems.

FAQ

What environments benefit most from brass deluge fire sprinkler heads?

Industrial sites, chemical plants, and refineries benefit most. These locations require rapid, area-wide fire suppression and demand materials that resist corrosion and extreme temperatures.

How does brass improve the reliability of deluge sprinkler heads?

Brass resists corrosion and mechanical wear. This property ensures long-term performance, even in harsh or wet environments. Fire safety professionals trust brass for consistent operation.

Are brass deluge heads compatible with modern fire protection systems?

Yes. Manufacturers design brass deluge heads to meet current safety standards. These heads integrate easily with advanced detection and control systems.

Post time: Jul-18-2025